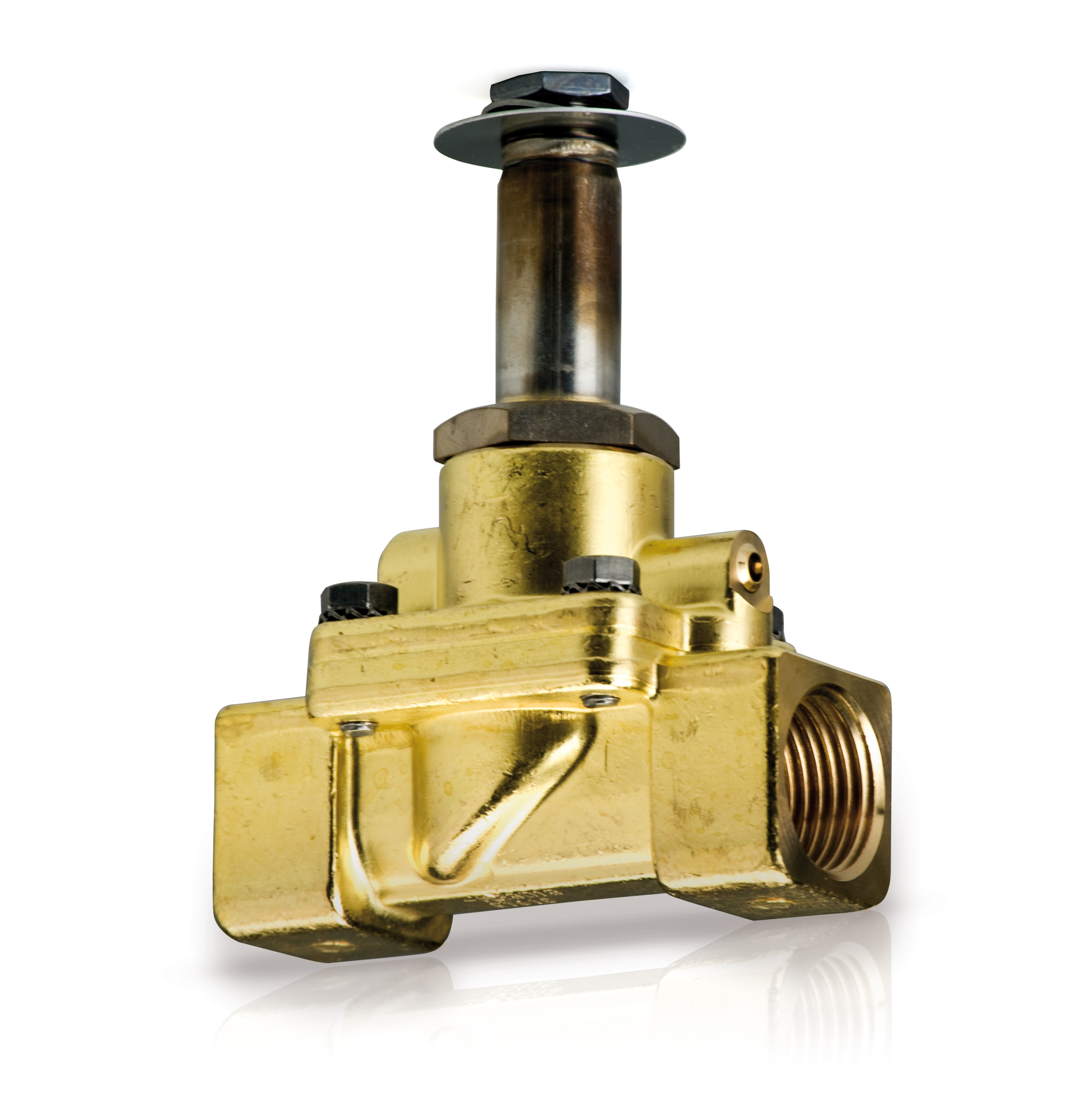

Servo-assisted diaphragm valve bodies, normally-closed

-

DESCRIPTION

General features0

Solenoid valves suitable for large flow capacity, suitable for water, air, fuel-oil, inert gases and other noncorrosive fluids, for copper alloys fluids with viscosity up to 2° Engler.

- Press-forged brass valve body OT58 UNI 5705.

- Gaskets in NBR (Buna N) – Viton.

- Rod in stainless steel AISI 304.

- Core in stainless steel AISI 430F.

- Spring in stainless steel AISI 302.

- Antivibration brass ring.

- Operating temperature: -10 ÷ 90°C.

ACCESSORIES

The control coils are supplied separately from valve bodies.

IM21D – Control coil 12Vac 50/60Hz

IM21F – Control coil 24Vac 50/60Hz

IM21H – Control coil 110Vac 50/60Hz

IM21M – Control coil 230Vac 50/60Hz

IM22 – Control coil 24Vdc (with coil in d.c. the indicated pressure should be reduced by 60%)

1578501 – Quick connection connector DIN 43650, suitable for all IM2 coils;

Cable gland Pg9 (cable diameter 6÷8 mm);

Pg11 cable gland thread;

Adjustable cable outlet in 4 positions every 90°. -

ADVANTAGES

0

Solenoid valves suitable for large flow capacity, suitable for water, air, fuel-oil, inert gases and other noncorrosive fluids, for copper alloys fluids with viscosity up to 2° Engler.

Advantages -

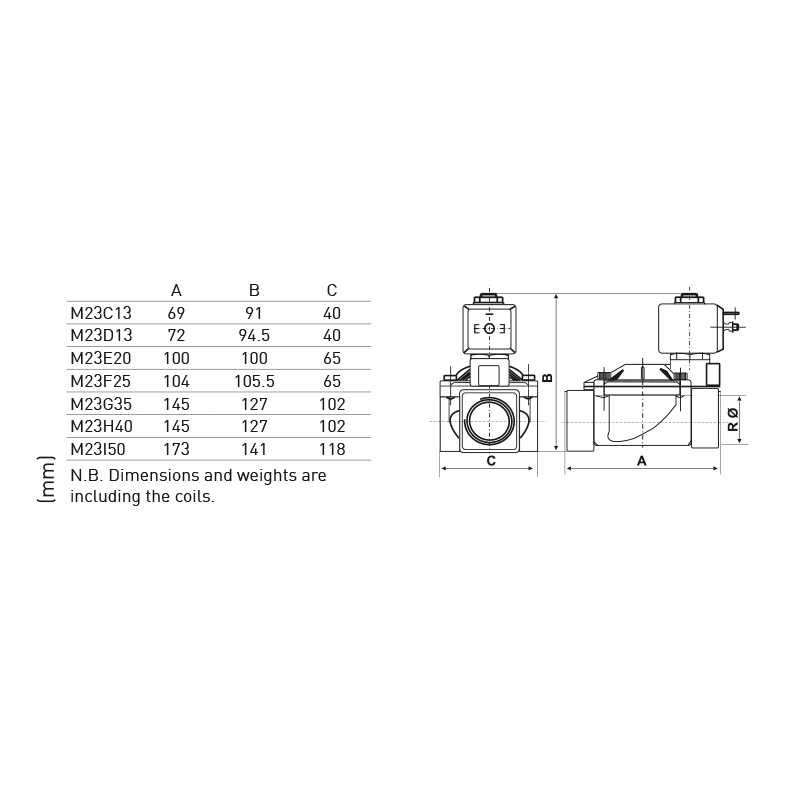

TECHNICAL SPECIFICATION

CODE PASSAGE ORIFICE DIAMETER FEMALE CONNECTION KV * CLOSING TIMEDP OF 1 BAR MINIMUM DIFFERENTIAL PRESSURE MAXIMUM DIFFERENTIAL PRESSURE TESTING PRESSURE (DIN2401) PN M23C13 13 mm G 3/8 3 1 sec. 20 bar 0.1 bar 25 bar M23D13 13 mm G 1/2 3 1 sec. 20 bar 0.1 bar 25 bar M23E20 20 mm G 3/4 8.4 1.5 sec. 20 bar 0.1 bar 25 bar M23F25 25 mm G 1 9.6 1.5 sec. 20 bar 0.1 bar 25 bar M23G35 35 mm G 1 1/4 25.2 2.5 sec. 10 bar 0.1 bar 16 bar M23H40 40 mm G 1 1/2 30 3 sec. 10 bar 0.1 bar 16 bar M23I50 50 mm G 2 37.2 3.5 sec. 10 bar 0.1 bar 16 bar Kv = water flow in m³/h with pressure drop of 1 bar (1 bar = 100kPa). -

HOMOLOGATION AND INSTALLATION

Homologation

- EN 60335-1:2013 + A11:2015

Installation and use- Female threaded connection from G 3/8 to G 2.

- The valves can be installed in any position.

- 2-way execution, normally-closed.

- Indirect operation with blocked servo-membrane.

- The fluid under pressure before the valve enters the space above the membrane, pressing it against the seat, blocking the passage.

- When the coil is energized, the pilot plug opens discharging the flow, therefore the media lifts the membrane disc, opening passage

orifice of the fluid.

- TECHNICAL LITERATURE

-

FAQS