Magnetic level control for under pressure systems up to 6 bar

-

DESCRIPTION

General features0

Suitable to control and adjust liquid level in small under pressure tanks (6 bar) such as sterilizers, autoclaves, steam machines, drink vending machines etc.

- Housing made of pressed stainless steel

- Float made of stainless steel AISI 304.

- Floating connection made of stainless steel AISI 430.

- Connections between the float and the level control made in stainless steel AISI 316

- Output connections with brass cable glands G 3/8.

- Storage and transport temperature: -25 ÷ 70 °C.

- Unit weight: 1.2 Kg.

Electric features- SPDT microswitch.

- Electrical connection with 6.35 Faston (supplied).

-

ADVANTAGES

0

Suitable to control and adjust liquid level in small under pressure tanks (6 bar) such as sterilizers, autoclaves, steam machines, drink vending machines etc.

Advantages -

TECHNICAL SPECIFICATION

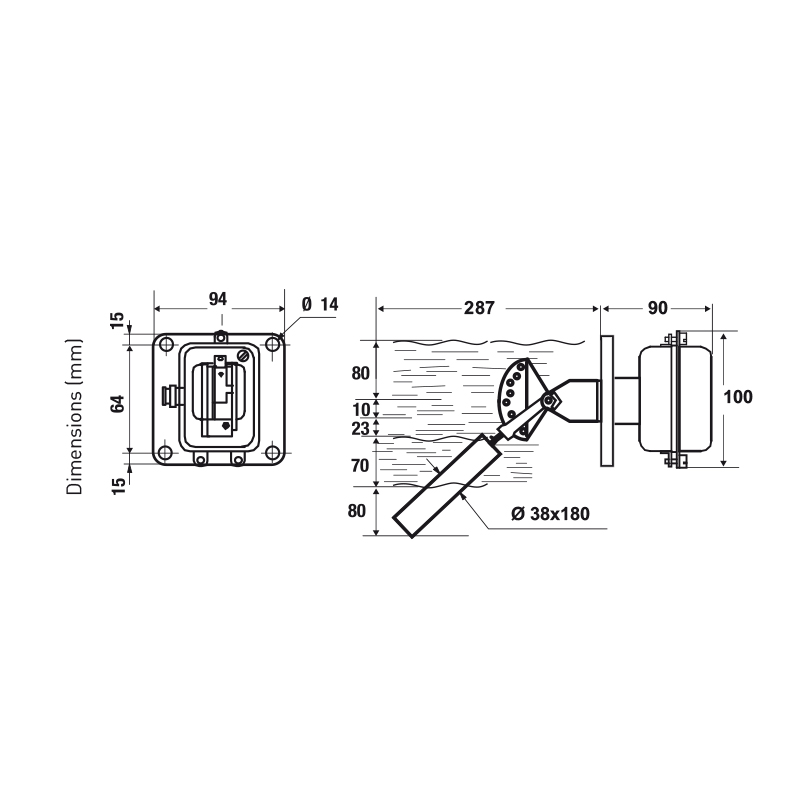

CODE LEVEL DIFFERENTIAL MAXIMUM OPERATING PRESSURE MATERIAL IN CONTACT WITH THE LIQUID CONTACTS RATING FLANGE CONNECTION PROTECTION DEGREE AD22 25 ÷ 175 mm 6 bar stainless steel 10(3)A 250Vca PN6 IP54 -

HOMOLOGATION AND INSTALLATION

Homologation

- Complies with CEI- EN 60947-5-1 standards.

Installation and use- Flange connection UNI 2223 – DIN32 – PN6.

- Fastening to the reservoir through a welded flange PN 6-DN 32.

- Coupling dimensions UNI 2223-67 with enlarged central hole.

- Sealing with 1 mm thickness gasket.

- Operation by means of repulsion of two permanent magnets in opposition.

- Controlled liquid must have a specific gravity from 0.7 to 1.1 kg/dm³ .

- When level increases: C-NC opens, C-NO closes.

- TECHNICAL LITERATURE

-

FAQS