Electromagnetic safety valves for air and gas

-

DESCRIPTION

General features0

Normally closed electromagnetic safety valves with quickly opening for air and non-aggressive gases (according to EN437).

- Voltage tolerance: -15% / +10%.

- Environment temperature: -15°C / +60°C.

- Closing time < 1 second.

- Protection degree: IP54.

- Cable gland: PG 9.

- Pressure inlets: G1/4” on two sides (except models with brass body).

- Gas type: Air and non-aggressive gases (EN 437).

- Filter: 600 μm (except models with brass body).

- Limit switch: by request from 3/4” to 4”.

- Possibility to connect a pressure gauge to monitor gas pressure (except models with brass body).

Electric features- Rated voltage: 230Vac – 50/60Hz or 24Vac/dc

- Upon request valves are available with coils for the following voltages:

-110V AC 50/60Hz

-24V AC/DC

-12V AC/DC

-

ADVANTAGES

0

Normally closed electromagnetic safety valves with quickly opening for air and non-aggressive gases (according to EN437).

Advantages -

TECHNICAL SPECIFICATION

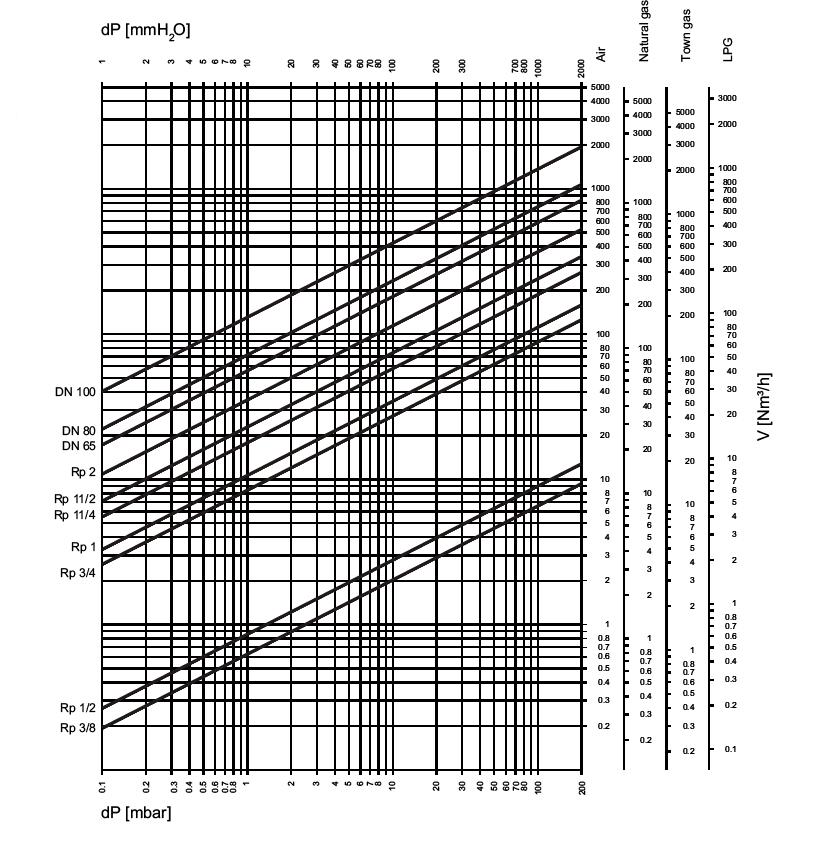

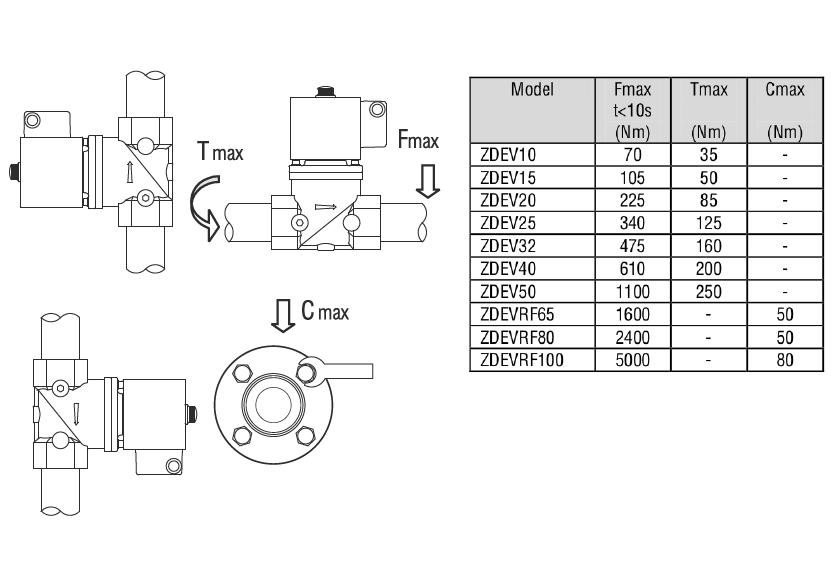

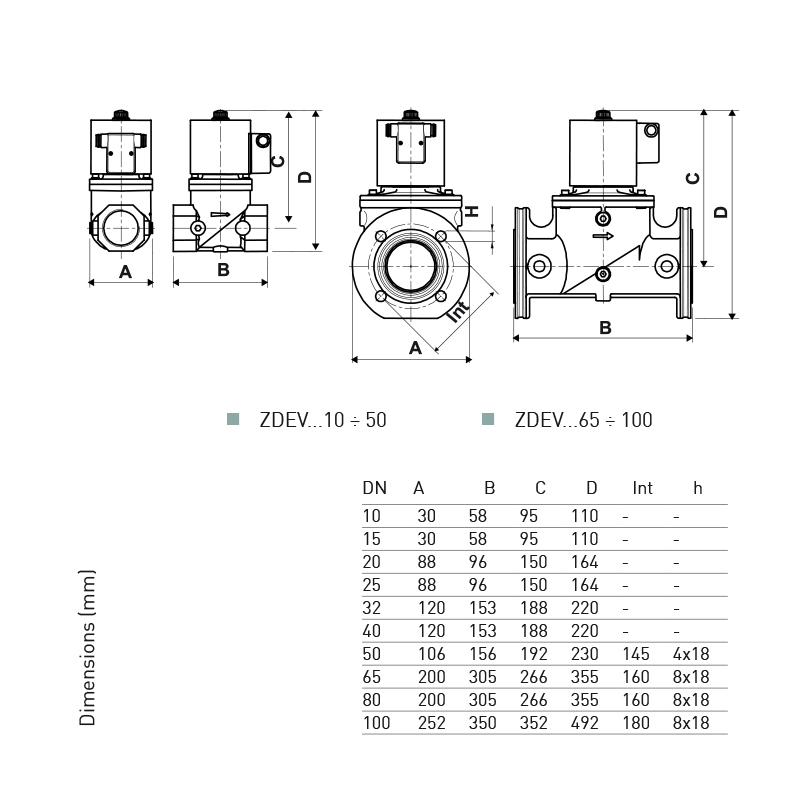

CODE CONNECTION TYPE PASSAGE DN POWER SUPPLY BODY MAXIMUM PRESSURE Mbar ABSORPTION W ZDEV10 threaded RP 3/8 10 230Vac 50/60Hz brass 200 16 ZDEV15 threaded RP 1/2 15 230Vac 50/60Hz brass 200 16 ZDEV20A threaded RP 3/4 20 230Vac 50/60Hz aluminum 500 45 ZDEV25A threaded RP 1 25 230Vac 50/60Hz aluminum 500 45 ZDEV32A threaded RP 1 1/4 32 230Vac 50/60Hz aluminum 500 20/80 ZDEV40A threaded RP 1 1/2 40 230Vac 50/60Hz aluminum 500 20/80 ZDEV50A threaded RP 2 50 230Vac 50/60Hz aluminum 500 20/80 ZDEVRF65 flanged DN 65 65 230Vac 50/60Hz aluminum 200 45/180 ZDEVRF80 flanged DN 80 80 230Vac 50/60Hz aluminum 200 45/180 ZDEVRF100 flanged DN 100 100 230Vac 50/60Hz aluminum 200 45/180 ZDEV10F threaded RP 3/8 10 24Vac brass 200 16 ZDEV15F threaded RP 1/2 15 24Vac brass 200 16 ZDEV20F threaded RP 3/4 20 24Vac aluminum 200 45 ZDEV25F threaded RP 1 25 24Vac aluminum 200 45 ZDEV32F threaded RP 1 1/4 35 24Vac aluminum 200 20/80 ZDEV40F threaded RP 1 1/2 40 24Vac aluminum 200 20/80 ZDEV50F threaded RP 2 50 24Vac aluminum 200 20/80 ZDEVRF65F flanged DN 65 65 24Vac aluminum 200 45/180 ZDEVRF80F flanged DN 80 80 24Vac aluminum 200 45/180 ZDEVRF100F flanged DN 100 100 24Vac aluminum 200 45/180 -

HOMOLOGATION AND INSTALLATION

Homologation

- Complies with 90/396/CEE (VMR-0063AQ1350), 73/23/CEE, 89/336/CEE standards

Installation and use- Check the correspondence between flow direction and the arrow printed on valve body, verify the correct alignment of connecting pipes and allow enough space from the walls to allow free air circulation. You should always install a filter before valve inlet (open <1 mm).

- The valve may be mounted with coil in horizontal or vertical position. The coil may be oriented 360 degrees in any direction. Install the valve in an area protected from rain and water splashes or drops.

- The flow rate is adjustable from 0 m³/h to the maximum indicated on the plate (except the models in brass and 4 “).

- Remove coil fastening cap, turn on the adjustment screw under the locking dowel.

- It is recommended to make the flow adjustments while the burner is in operation and when the adjustment is completed screw back the locking dowel.

- Adjustments below 40% of the flow are unadvisable since they may cause turbulence.

- Fast opening gas safety electromagnetic valve that is normally closed.

- When it is not energized, the spring works on the shutter keeping the gas passage closed.

- When the coil is feed the valve opens.

- When the power supply is interrupted the valve rapidly closes.

- This device is suitable for gas and air blocking and regulation commands in burners at atmospheric pressure or fan-assisted burners, in industrial ovens and in all applications which use gas solenoid valves (suitable for continuous service – 100% ED).

- TECHNICAL LITERATURE

-

FAQS